-

Product

-

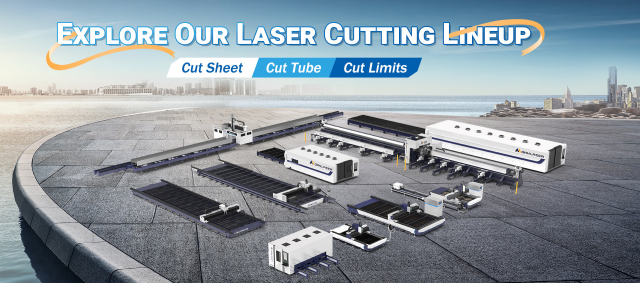

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Fiber Laser Cutting vs. CO2: A Complete Comparison of Precision, Efficiency, and Cost

2025-10-30In the world of laser cutting, two core technologies have defined the industry's evolution — fiber laser cutting machines and CO2 laser cutting machines. Both have their place, but with the rapid advancement of fiber laser technology, many manufacturers are now rethinking their equipment choices. So which one truly leads the future of metal cutting? Let's take a closer look.

1.Cutting Principle and Performance

Fiber laser cutting machines use optical fibers doped with rare-earth elements as the gain medium. This design converts electrical energy into laser energy with exceptional efficiency. The result? Faster cutting speeds, higher energy conversion rates, and outstanding performance in metal cutting applications, such as stainless steel, aluminum, and brass.

In contrast, CO2 laser cutting machines use gas excitation to generate a laser beam, which is then reflected through mirrors and focused to cut materials. This mature technology delivers stable cutting performance, especially for non-metal materials like wood, acrylic, and plastic.

2. Efficiency and Operating Cost

Here's where fiber laser cutting truly shines. A fiber laser consumes only one-third of the power required by an equivalent CO2 system, translating into substantial long-term savings on energy costs.

Maintenance is also minimal. With no mirrors or laser gas, fiber lasers have fewer consumable parts and longer service life. CO2 machines, on the other hand, require frequent mirror alignment, gas refills, and maintenance, leading to higher downtime and total cost of ownership.

3. Precision and Cutting Quality

When it comes to precision, fiber laser cutting equipment leads the race. Their shorter laser wavelength (1.06 μm) allows for tighter focusing, resulting in finer cuts and smoother edges.

CO2 lasers (10.6 μm wavelength) are better suited for thicker non-metal materials but struggle with reflective metals due to beam reflection, which can damage internal components. For manufacturers focusing on metal processing, fiber laser technology is the more accurate, reliable, and future-proof option.

4. Application Scenarios

If your production involves mainly non-metal materials, such as acrylic displays, wooden crafts, or packaging materials, CO2 lasers still hold value.

However, for industries like automotive, sheet metal fabrication, machinery manufacturing, and electrical enclosures, a fiber laser cutting machine is the clear winner. It delivers faster cutting, cleaner edges, and greater cost efficiency.

5. Investment and ROI Considerations

While fiber laser cutting machines come with a higher initial investment, the long-term benefits far outweigh the cost. Their lower maintenance, higher speed, and energy savings deliver a faster return on investment. Many industry-leading brands and laser cutting equipment manufacturers now recommend fiber technology as the standard for modern production lines.

The shift from CO2 to fiber laser cutting is more than a technology upgrade. It represents a transformation in manufacturing philosophy. As factories around the world pursue smarter, greener, and more efficient production, fiber laser cutting leads the way in this revolution.

If you're evaluating laser cutting machines or struggling with cutting quality issues, our experts can help. As a professional laser cutting machine manufacturer, we offer tailored solutions to meet your material, thickness, and production needs.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()