-

Product

-

Fiber laser cutting machine

-

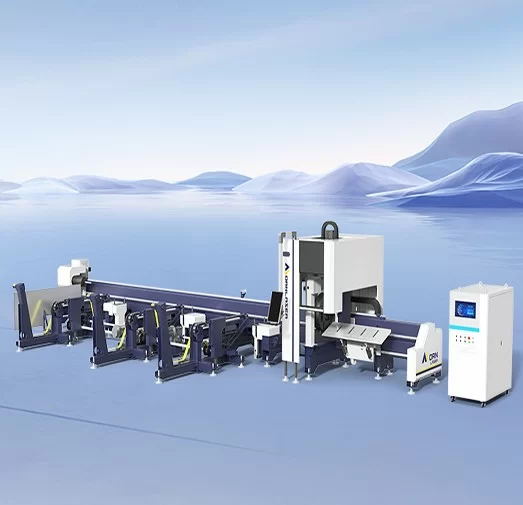

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

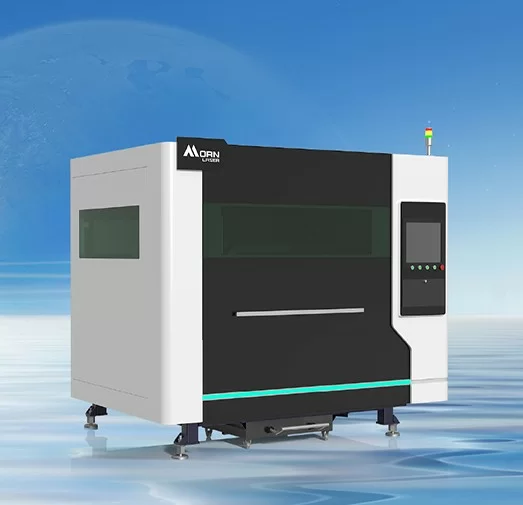

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

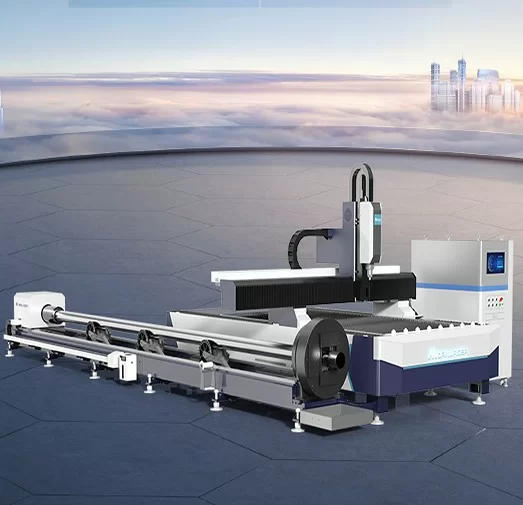

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

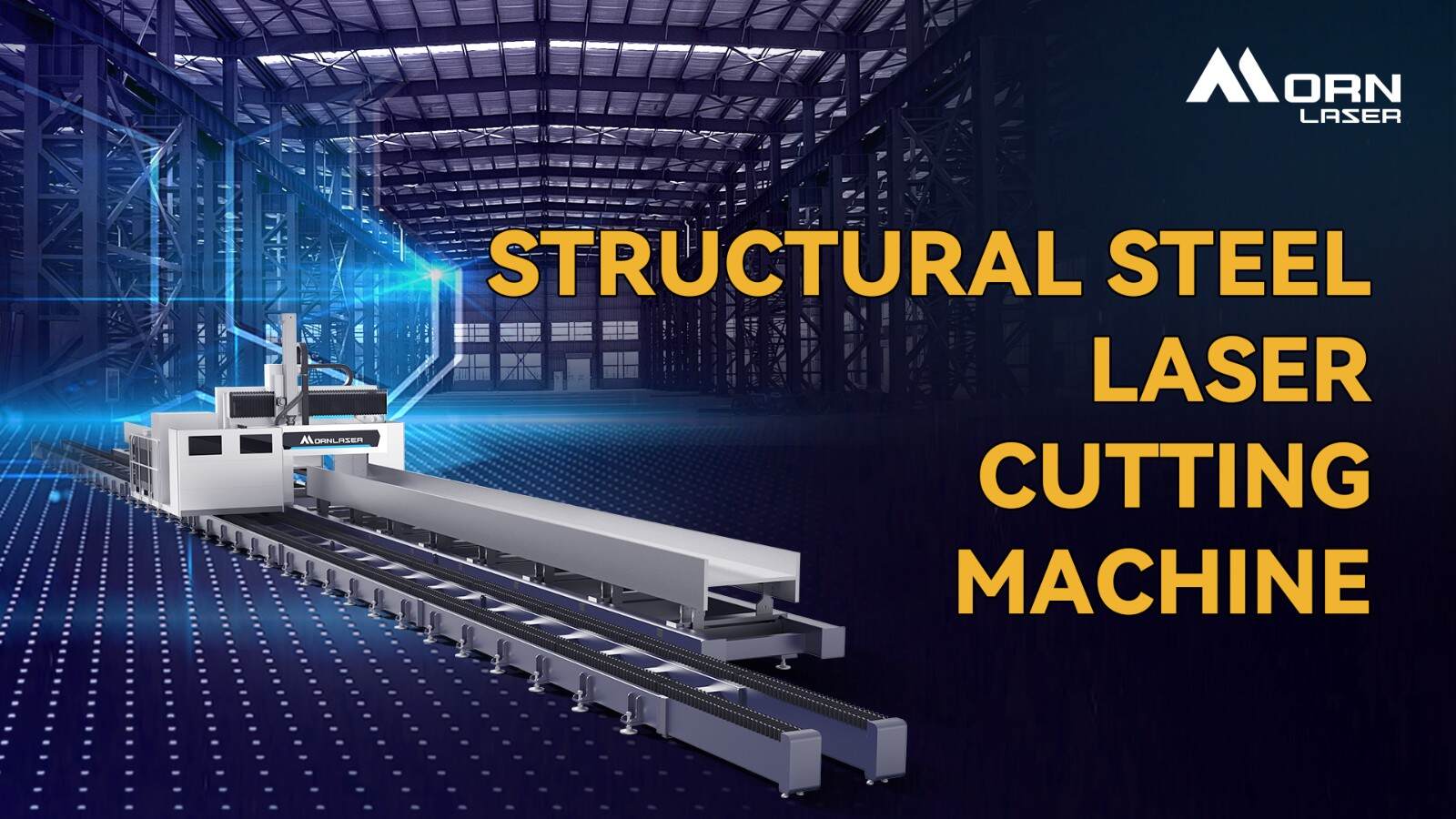

Break through limitations and subvert traditional processes One-stop laser solution for the steel structure industry

Profile Steel/ H-Beam Laser Cutter

±0.25mmX/Y axis positioning accuracy±0.05mmX/Y axis re-positioning accuracy30m/minX/Y/Z maximum speed12-20kWLaser power![Profile Steel/ H-Beam Laser Cutter]()

Benefits you can get from our structural steel laser cutting machine

![]() High efficiency

High efficiency![]() Strong adaptability

Strong adaptability![]() High cost performance

High cost performance![]() Low labor cost

Low labor cost![Video Thumbnail]()

![youtube]()

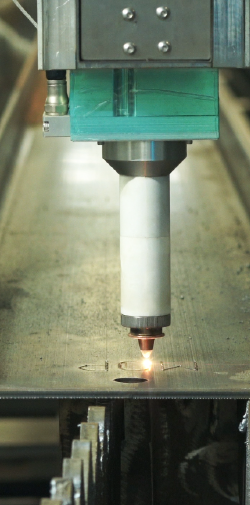

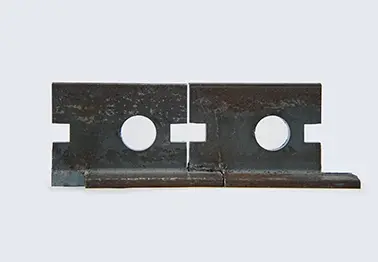

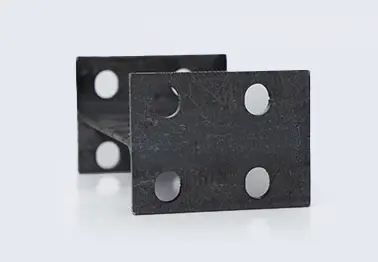

![laser cutting]() marking

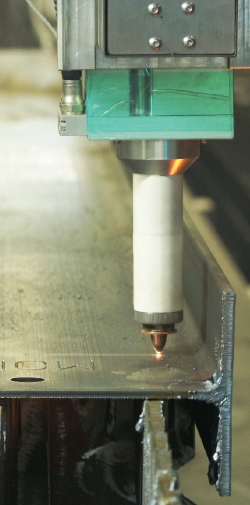

marking![laser cutting]() web piercing

web piercing![laser cutting]() overweld hole cutting

overweld hole cutting![laser cutting]() bevel cutting

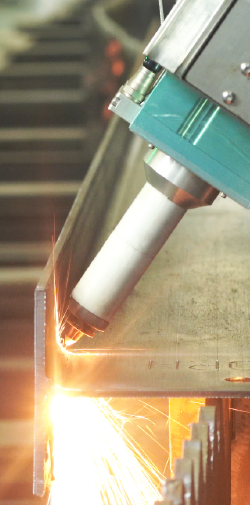

bevel cutting![laser cutting]() lineation

lineation![laser cutting]() cutoff

cutoffMultiple processes, one-stop solution

Marking, web piercing, overweld hole cutting, bevel cutting, cutoff and other processes can be done with one machine

![Laser cutting machine]()

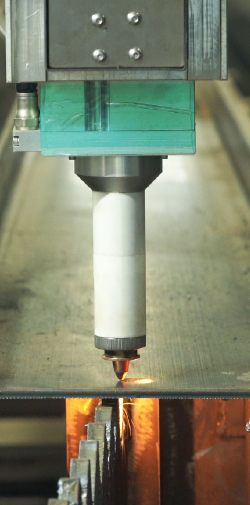

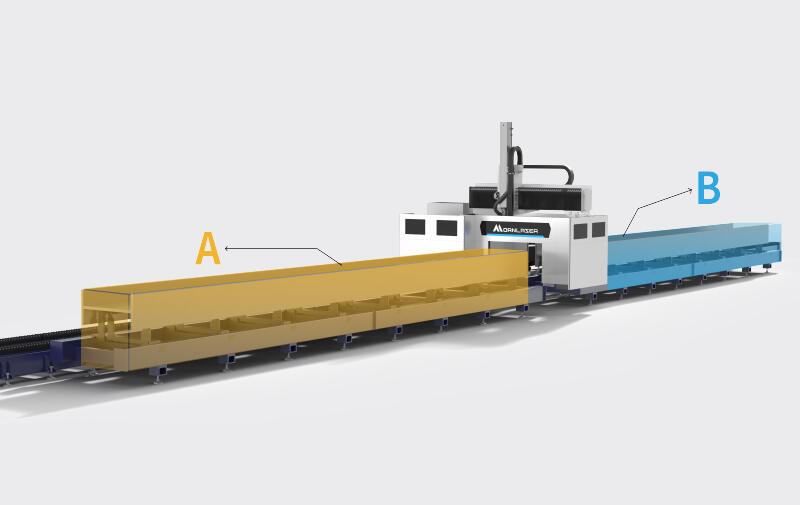

Double-station design

Cutting and loading & unloading can be performed simultaneously, saving time and labor costs

![Laser cutting machine]()

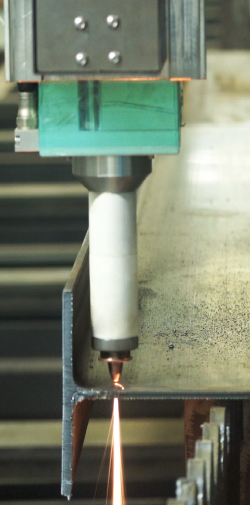

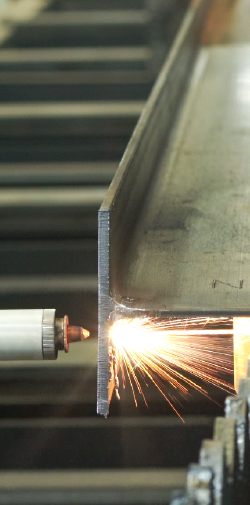

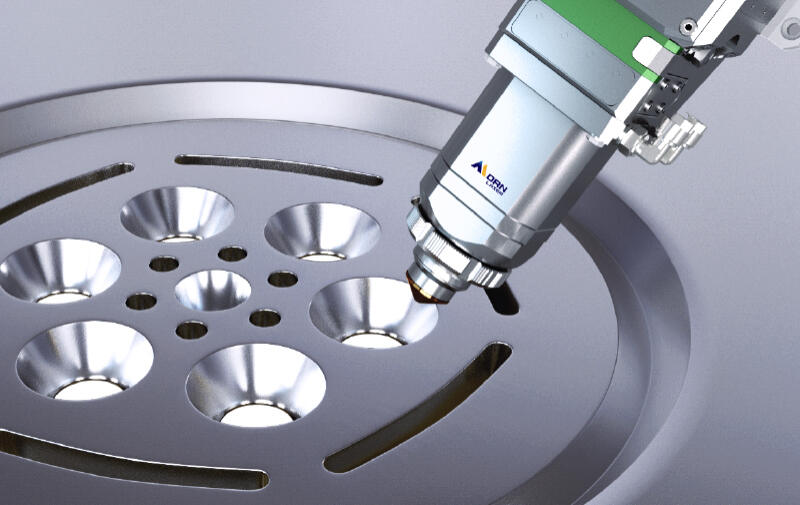

+45° bevel cutting

Supports one-step forming of X//V/K-shaped bevel cutting, increasing efficiency by more than 75%

You may also find these topics interesting

It can stably clamp round tubes, square tubes, I-beams, channel steels, special-shaped tubes, etc., to achieve efficient and stable cutting. It can be equipped with an automatic feeding system to achieve super-strong feeding and improve cutting efficiency.

Change instantly from sheet to tube without the need for additional setup or tooling. Use your time making products instead of making changeovers. It’s the ideal way to maximize your return on investment.

Fully enclosed integrated design, smaller footprint, safer and more reliable processing. The processing effect is more refined, and small workpieces can be precisely cut.

It can stably clamp round tubes, square tubes, I-beams, channel steels, special-shaped tubes, etc., to achieve efficient and stable cutting. It can be equipped with an automatic feeding system to achieve super-strong feeding and improve cutting efficiency.

Change instantly from sheet to tube without the need for additional setup or tooling. Use your time making products instead of making changeovers. It’s the ideal way to maximize your return on investment.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()