-

Product

-

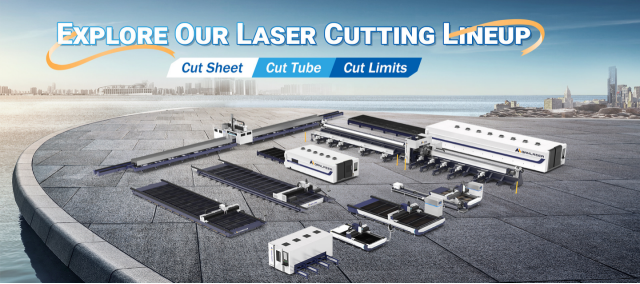

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

An In-Depth Look at the Working Principle and Core Advantages of Fiber Laser Cutting Machines

2025-10-23In modern manufacturing, fiber laser cutting machines represent the perfect dialogue between light and steel. They turn invisible laser beams into precise, powerful tools. These machines are changing the way we process metal. Understanding how they work and why they perform better than traditional methods helps businesses choose the right brand and manufacturer for long-term success.

1. The Science Behind Fiber Laser Cutting

At the heart of every fiber laser cutting machine lies a solid-state laser source. Unlike CO₂ or YAG lasers, fiber laser sources use optical fibers doped with rare-earth elements to generate a high-intensity beam. The light then transmitted through fiber cables to the cutting head, keeping its beam quality and energy density even over long distances.

How the Process Works

Laser generation – The fiber laser source produces a concentrated, coherent light beam.

Beam transmission – The beam travels through fiber optics without loss of power.

Focusing and cutting – The cutting head focuses the beam into a microscopic spot, instantly melting and vaporizing the metal.

Assist gas – Oxygen, nitrogen, or air blows away molten material, creating smooth, burr-free edges.

This seamless interaction between light and metal gives fiber laser cutting its unmatched precision and speed. It is the result of decades of innovation by leading laser cutting machine manufacturers.

2. Core Technologies that Define Modern Fiber Laser Cutting

Behind the clean cut lies a combination of advanced technologies that elevate modern laser cutting equipment above conventional systems.

- High Beam Quality and Power Density

Fiber lasers maintain near-perfect beam consistency, enabling ultra-fine cutting gaps and minimal heat-affected zones. This means cleaner edges, reduced distortion, and faster cutting speeds even on reflective materials like aluminum and copper.

- Intelligent Control Systems

Today's top laser cutting machine manufacturers integrate CNC controls with intelligent automation. Features such as auto-focus, real-time monitoring, and smart piercing optimize cutting for different materials and thicknessesThis helps reduce waste and increase uptime.

- Efficient Energy Utilization

Fiber lasers convert up to 40% of electrical energy into light, making them several times more efficient than traditional laser systems. This translates to lower energy costs and sustainable production, an advantage recognized by many recommended brands.

3. Why Fiber Laser Technology Outperforms Traditional Cutting

The shift from mechanical and plasma cutting to fiber laser cutting machines is driven by clear performance advantages:

Precision: high accuracy for complex geometries.

Speed: Up to 3–5 times faster than CO₂ laser cutting.

Low Maintenance: Fewer optical components and no alignment needed.

Versatility: Cuts steel, stainless steel, aluminum, brass, and even titanium.

Sustainability: Cleaner processing and reduced material waste.

Partnering with a trusted laser cutting machine manufacturer ensures access to cutting-edge designs and after-sales support that maximize these advantages.

4. Application Scenarios: Where Fiber Laser Cutters Reshape Industry

From small workshops to heavy industry, fiber laser cutting machines have become the cornerstone of metal fabrication.

Automotive manufacturing: High-speed precision cutting for chassis and components.

Shipbuilding and construction: Efficient processing of thick, large-format steel plates.

Electrical enclosures and sheet metal fabrication: Seamless production with automated systems.

Aerospace and high-end machinery: Consistent quality for high-precision parts.

As Industry 4.0 advances, laser cutting machine manufacturers are pushing fiber laser technology into the next generation. Future systems will feature:

AI-driven cutting optimization for real-time parameter adjustment

IoT-enabled remote diagnostics for predictive maintenance

Integrated automation lines for fully unmanned production

These developments will further expand the dialogue between light and metal — enabling manufacturers to achieve higher precision, lower cost, and greater competitiveness.

Fiber laser technology is redefining the boundaries of what's possible in metal processing. When you choose a reputable brand and partner with a trusted laser cutting machine manufacturer, you're not just upgrading your equipment. You're embracing the future of intelligent manufacturing.

If cutting quality or efficiency is holding your production back, contact our technical experts today for a one-on-one consultation.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()