-

Product

-

Fiber laser cutting machine

-

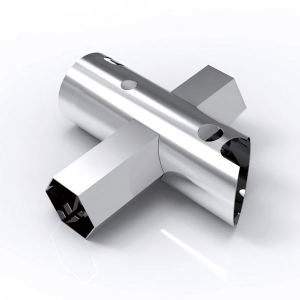

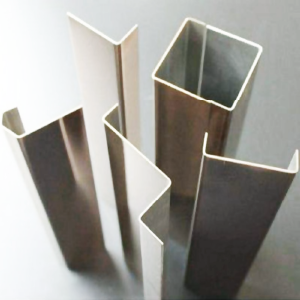

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

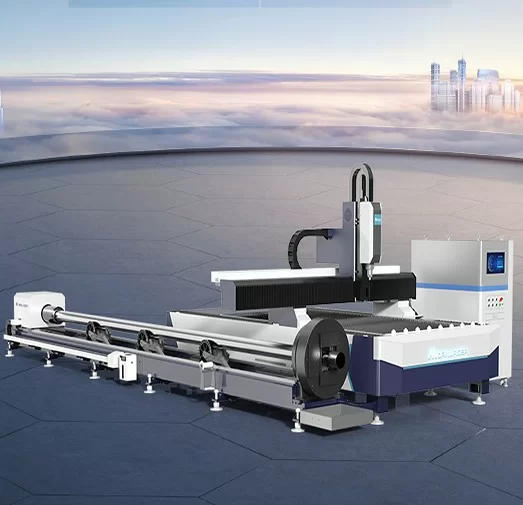

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

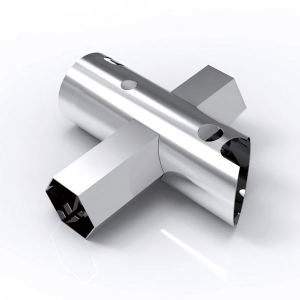

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

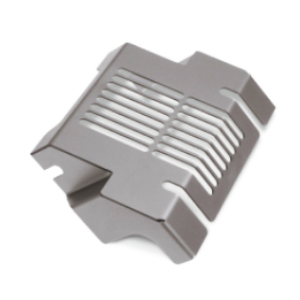

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

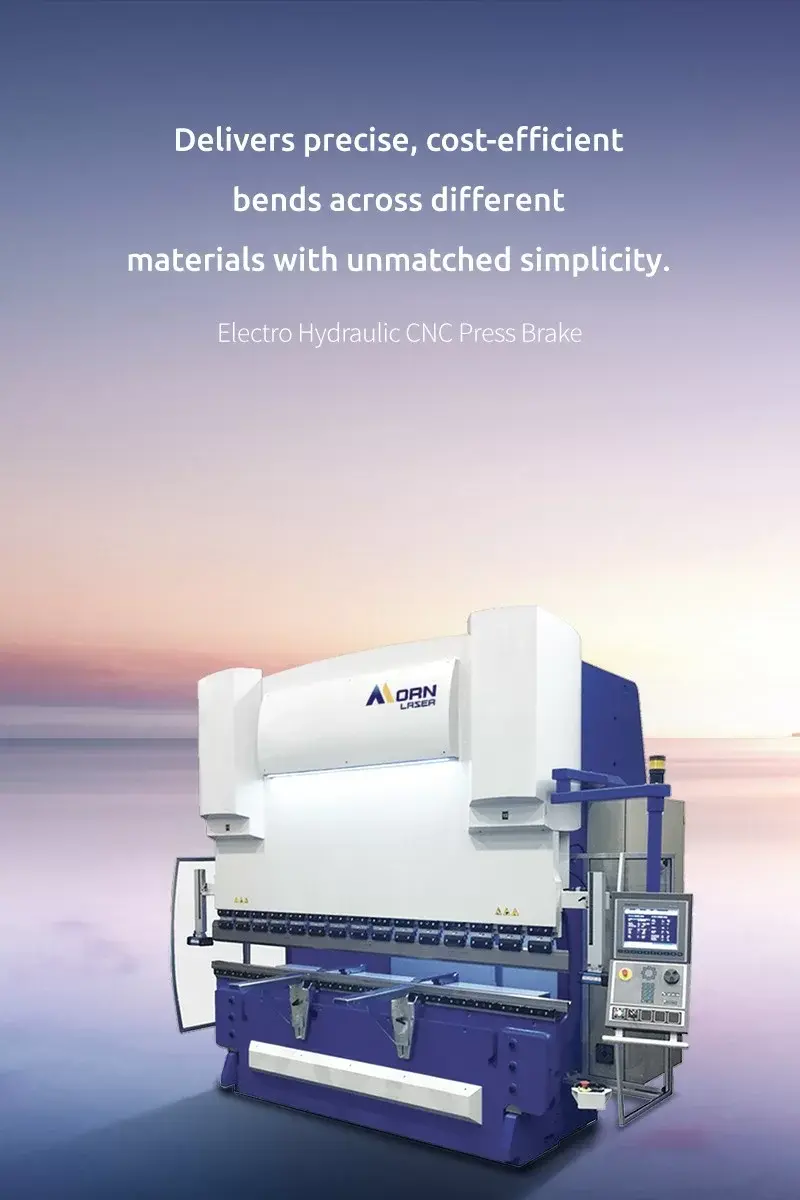

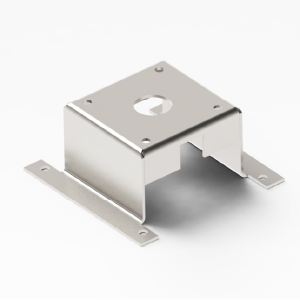

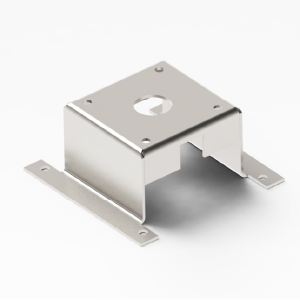

Electro Hydraulic CNC Press Brake

Electro Hydraulic CNC Press Brake

![Electro Hydraulic CNC Press Brake]() Benefits you can get from our CNC sheet metal bending machine

Benefits you can get from our CNC sheet metal bending machine![]() Stable performance

Stable performance![]() Easy operation

Easy operation![]() High efficiency

High efficiency![]() Energy saving

Energy saving![Video Thumbnail]()

![YouTube Logo]()

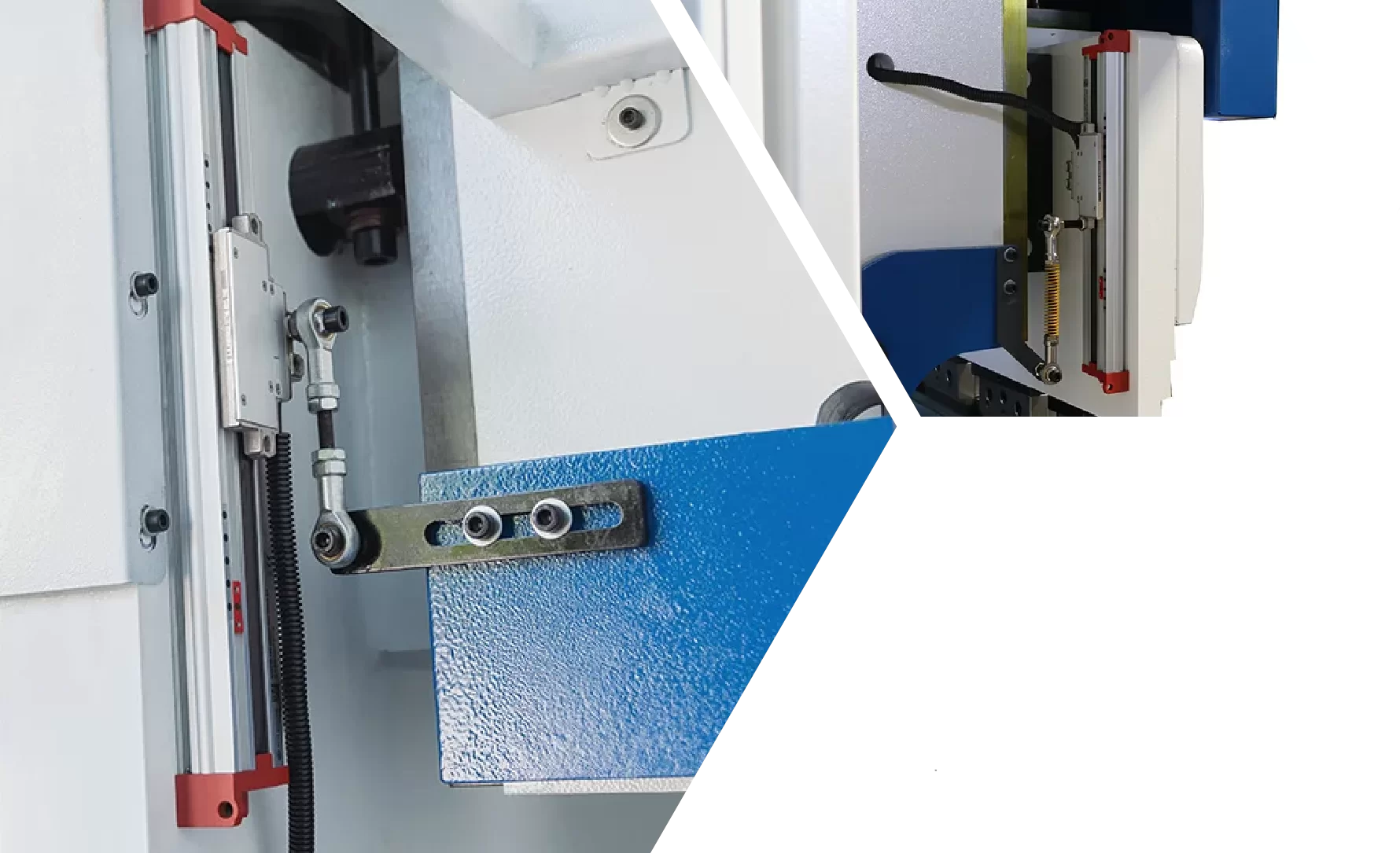

The push-pull upper module quick clamping device offers high precision and easy module changes, significantly boosting production speed.

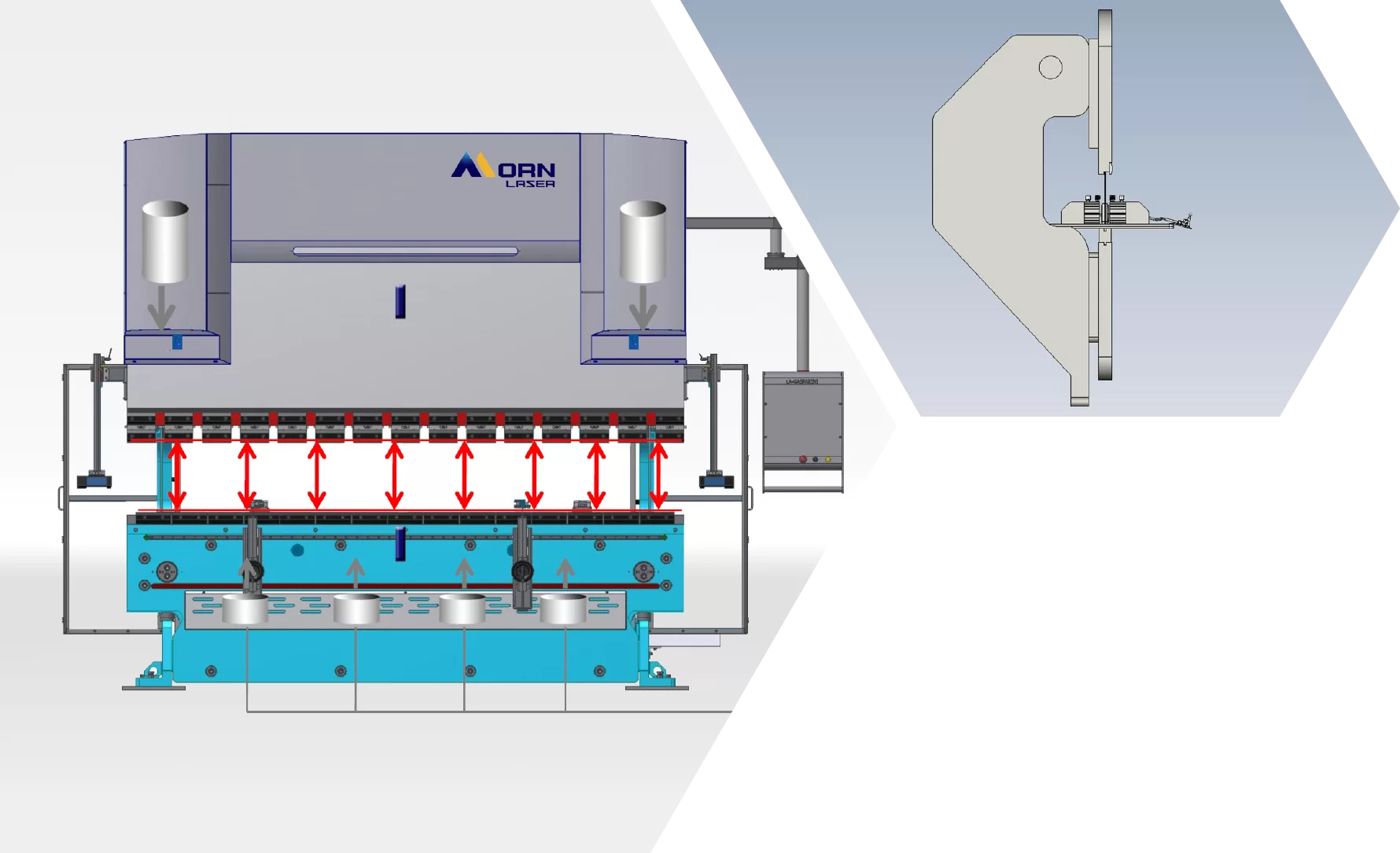

Eliminates slider deformation effects, with automatic compensation adjustments for easy and accurate operation.

Automatically detects angle errors and adjusts cylinder stroke configuration, offering high displacement accuracy and fast response speed.

Quick Clamping DeviceMechanical Deflection CompensationOptical ScaleTechnical Data FeaturesMachine Type

30T/1600

40T/2500

63T/2500

80T/2500

100T/5000

125T/2500

160T/5000

200T//4000

250T/4000

Nominal Force (KN)

300

400

630

800

1000

1250

1600

2000

2500

Worktable length (mm)

1600

2500

2500

2500

5000

2500

5000

4000

4000

Poles Distance (mm)

1340

2000

2000

2000

4000

2000

4000

3100

3100

Throat Depth (mm)

180

220

300

300

400

400

400

400

400

Slider Travel (mm)

80

120

120

120

160

160

200

200

250

Height of Max Open (mm)

250

320

370

370

410

410

460

470

550

Highlights describe Environmentally friendly and efficient operation Energy-saving, eco-friendly, and high-efficiency CNC bending machine Closed loop servo hydraulic system Equipped with a unique closed-loop servo hydraulic system for superior economic performance Top brand servo drive Back gauge driven by a digitally controlled AC servo motor from a globally renowned brand High precision transmission system Precision ball screw drive with large lead, guided by linear guide rails for enhanced accuracy Application & bending samples

Favored by automotive manufacturing, construction engineering, machinery manufacturing, sheet metal processing, and construction industriesthis CNC press brake is perfect for bending metal plates, including carbon steel, stainless steel, aluminum, and copper.

Application & bending samples

Favored by automotive manufacturing, construction engineering, machinery manufacturing, sheet metal processing, and construction industriesthis CNC press brake is perfect for bending metal plates, including carbon steel, stainless steel, aluminum, and copper.

You may also find these topics interesting

Change instantly from sheet to tube without the need for additional setup or tooling. Use your time making products instead of making changeovers. It’s the ideal way to maximize your return on investment.

Long and heavy tube cutting expert, truly zero-tailing. Make full use of your tube with this four-chuck tube laser cutting machine. Automatic bundle loader brings efficient production of big lots.

With an integrated design, no disassembly is needed for delivery, and it can be directly put into a container, saving shipping cost.

Change instantly from sheet to tube without the need for additional setup or tooling. Use your time making products instead of making changeovers. It’s the ideal way to maximize your return on investment.

Long and heavy tube cutting expert, truly zero-tailing. Make full use of your tube with this four-chuck tube laser cutting machine. Automatic bundle loader brings efficient production of big lots.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()