-

Product

-

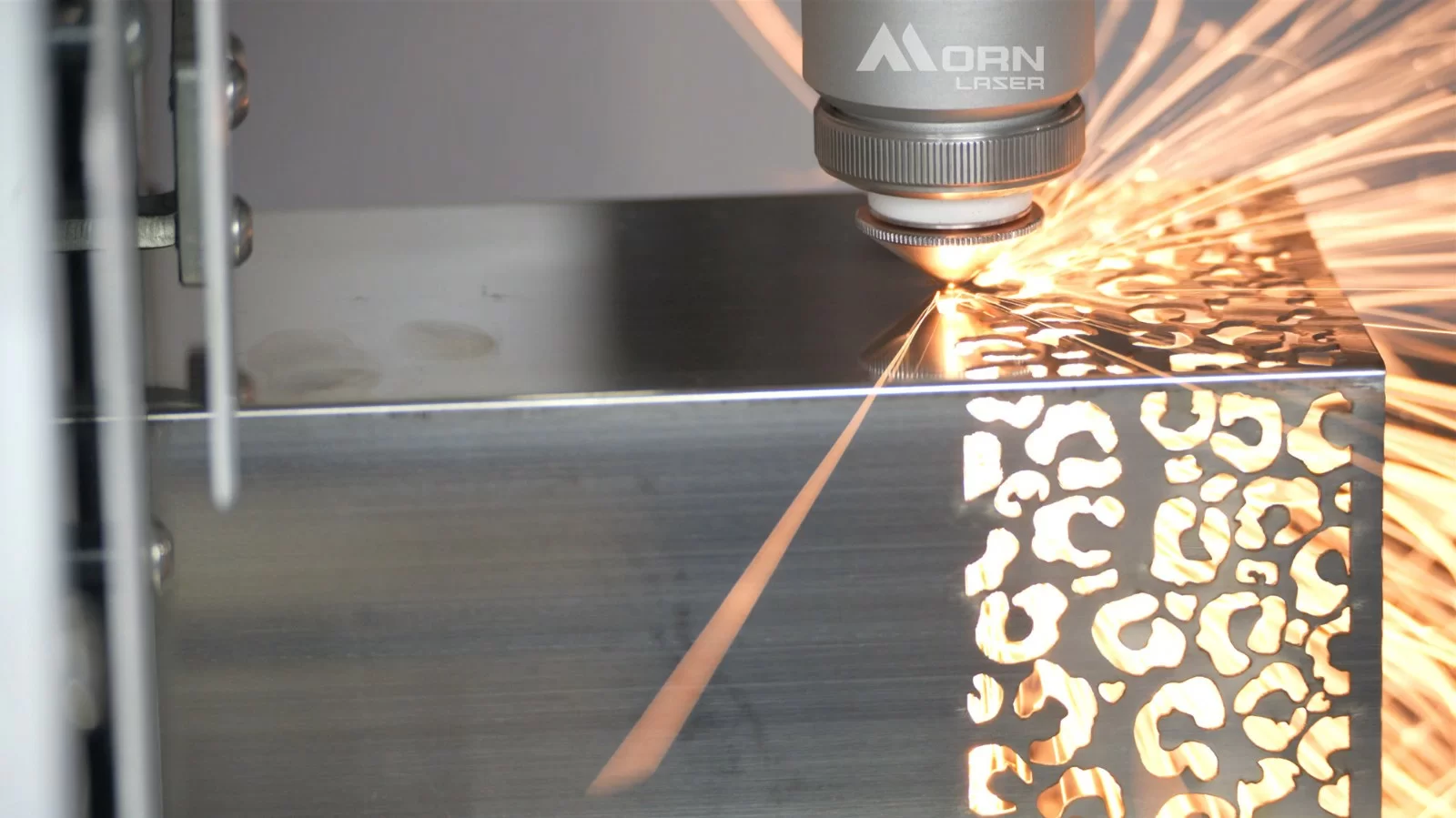

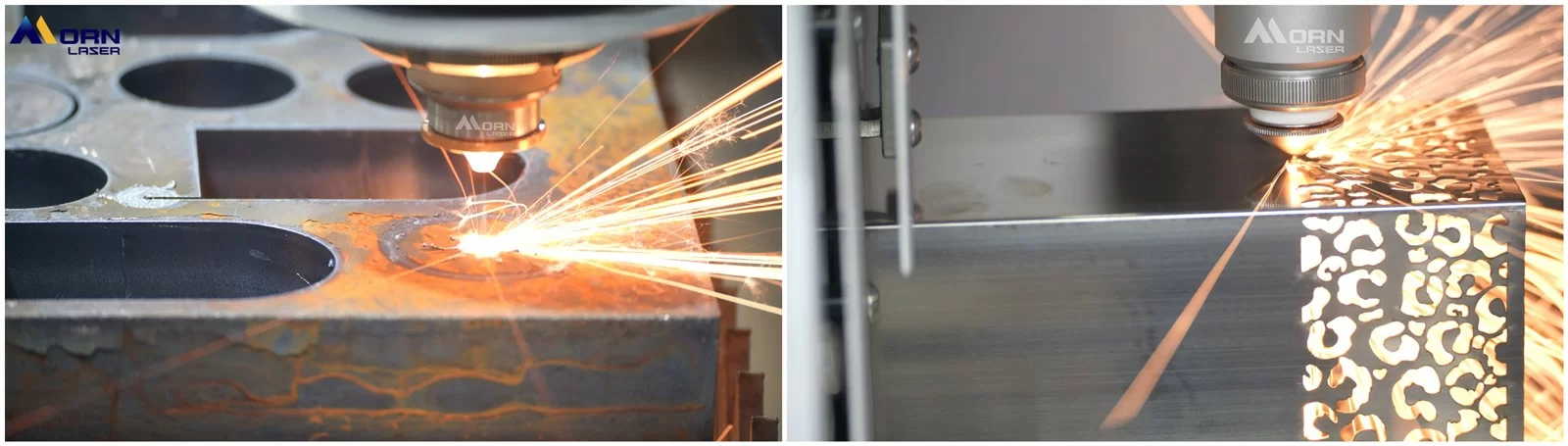

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Pricing

- Contact

Menu

X- home

-

Product >

-

![News]()

News

-

As customer demands for customized, fast, and precise tube fabrication increase, more manufacturers are turning to tube laser cutting machines—especially in industries like furniture, automotive, gym

2025-06-0505 2025-06 -

Once considered futuristic, laser welding is now widely used across industries, from stainless steel fabrication to auto parts repair and even fine metalwork. But how does it really compare to traditi

2025-05-2828 2025-05 -

When expanding your metal fabrication capabilities, choosing between a tube laser cutting machine and a plate laser cutting machine can be a tough decision. This article breaks down the key differenc

2025-05-2121 2025-05 -

If you're cutting thick metal sheets, high-speed production lines, or tackling demanding projects in industries like shipbuilding, construction, or railway manufacturing, you need a machine that deliv

2025-05-1414 2025-05 -

A fiber laser cutting machine is one of the most powerful tools in modern metal fabrication, capable of delivering high-speed, high-precision cutting for a wide range of materials. But with so many mo

2025-05-0909 2025-05

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()

-