-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Tube vs Plate Laser Cutting Machines: Which One Do You Really Need?

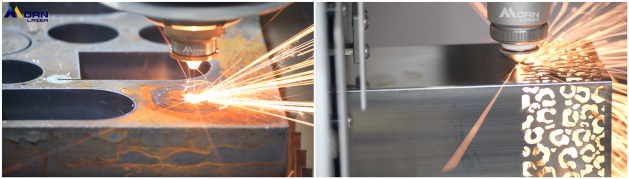

2025-05-21When expanding your metal fabrication capabilities, choosing between a tube laser cutting machine and a plate laser cutting machine can be a tough decision. While both are powered by fiber laser technology and offer high precision and speed, they are designed for distinct purposes.

So—do you really need both? Or should you specialize?

This article breaks down the key differences, advantages, and ideal use cases of each machine to help you make the right investment for your business.

1. What’s the Difference in Design?

Sheet Metal Laser Cutting Machine

- Designed for flat sheet metal

- Common formats: 3015 (1500mm x 3000mm), 4020, 31140 etc.

- Handles materials like carbon steel, stainless steel, aluminum, brass

- Supports nesting of multiple parts on one sheet

Tube Laser Cutting Machine

- Specialized for round tubes, square tubes, rectangular pipes, and sometimes angle/channel steel

- Supports automatic feeding, bevel cutting, and slotting

- Common sizes: Supports diameter 20–220mm, length 6–12 meters

2. Key Differences at a Glance

Feature

Metal Plate Laser Cutter

Metal Tube Laser Cutter

Cutting Target

Flat metal sheets

Metal tubes and pipes

Material Handling

Manual or automatic

Auto-feeder

Shape Complexity

2D, 3D flat profiles

2D, 3D profiles, holes

Common Industries

General sheet metal, machinery

Furniture, fitness, pipeline

3. Which One Should You Choose?

Let’s break it down by application scenarios:

√ Choose a Plate Laser Cutter If:

Your core business is sheet metal fabrication

You make enclosures, covers, flat components

You process varied sheet thicknesses regularly

Your customers prioritize fast turnaround and high efficiency

√ Choose a Tube Laser Cutter If:

You focus on metal furniture, gym equipment, bike frames, pipelines

You need precise holes, notches, or joints on tubes

You want to eliminate secondary drilling or milling processes

You process high volumes of steel tubes

√ You May Need Both If:

You run a custom fabrication shop

You handle both structural frames and sheet metal parts

You want to offer end-to-end laser cutting services

Morn Laser offers integrated metal sheet and tube laser cutting machine (dual-use models), ideal for mixed processing needs.

4. Smart Automation and Efficiency

Tube laser systems are often equipped with:

Automatic loading/unloading

Self-centering chucks

3D cutting heads for bevel cutting

Plate laser systems focus more on:

Sheet nesting optimization

High-speed cutting

Auto-focus cutting heads

Edge tracking for irregular sheets

Both machine types can be upgraded with smart automation for unattended production and error reduction.

5. What Does Morn Laser Offer?

Morn Laser provides:

√ Dedicated machines:

Plate-only (3015/4020/2560/31140 series)

Tube-only (P-series with 4-chuck, 3-chuck or 2-chuck design)

√ Dual-use machines:

metal sheet and tube laser cutter

√ Custom solutions:

For large-diameter tubes or complex material handling

OEM/ODM options available

The right choice depends on your production focus and long-term goals. If you’re in general sheet metal processing, a plate laser cutter is the core tool. If you’re in structural design, tubular product manufacturing, or specialized fabrication, tube laser machines offer a major productivity edge.

Still unsure which one to choose? Let our specialists analyze your application and provide a tailored laser solution.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()