-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

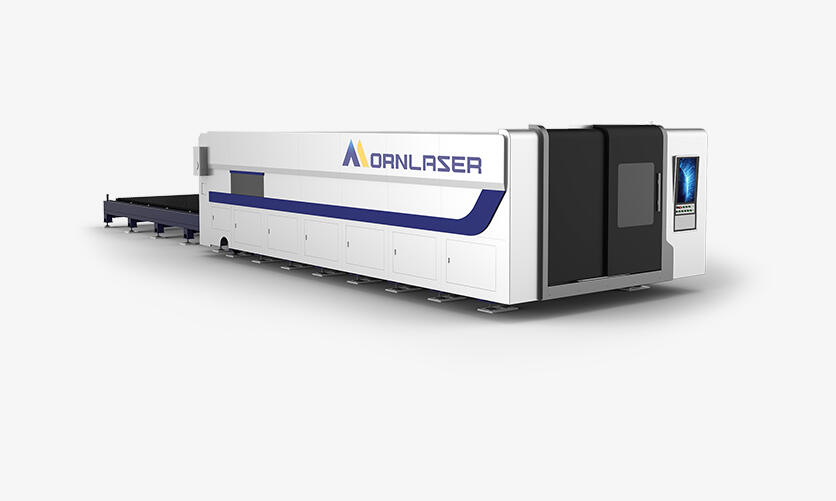

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

What Does “Good Cutting” Really Mean When Fiber Lasers Cut Stainless Steel?

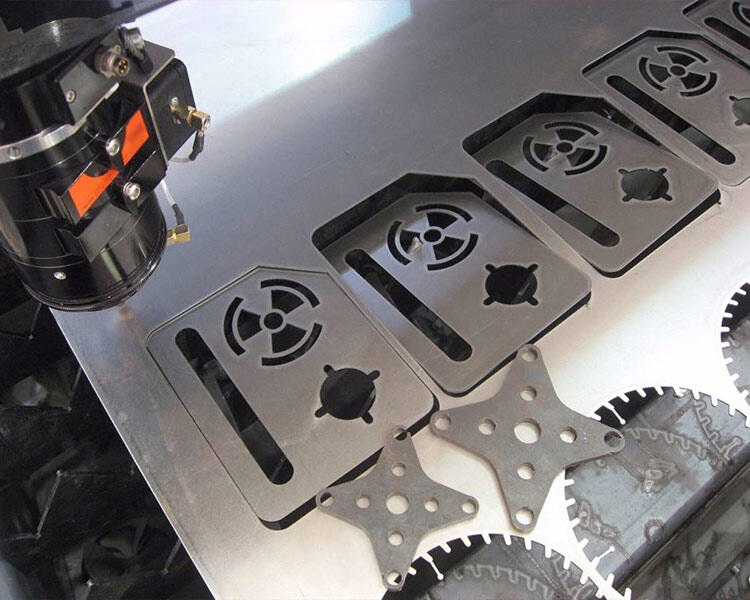

2025-12-09In a workshop, a sheet of stainless steel is fed into a laser cutting machine. A few seconds later, a clean slit appears and the part drops out easily.

Looks simple, right?

But if you look closely, you’ll notice something interesting:

Some cuts are smooth and shiny, like polished artwork;

Others look rough, dark, or have dross hanging at the bottom, sometimes requiring secondary grinding.

So what makes the difference?

The key isn’t how expensive the machine is — it’s how you use it.

Fiber laser cutting machines have become the standard in metal fabrication, especially for stainless steel. They offer high speed, low energy consumption, and require less maintenance than CO₂ lasers.

Yet many users buy a high-power fiber laser only to discover:

“Why do other shops get mirror-smooth edges, while I still need rework?”

The truth is, achieving high-quality stainless steel cutting isn’t about mysterious “high-tech secrets.”

It’s about mastering a few simple but critical fundamentals.

Below are the practical techniques that anyone can apply.

1. Higher Power Doesn’t Mean Better Cutting — Matching Matters More A common question:

“If I want to cut 6 mm stainless steel, do I need a 10 kW or 12 kW laser?”

Not necessarily.

Laser power does affect capability, but the quality of the cut depends on using energy wisely, not excessively.

Example:

Cutting 1 mm thin sheet → a 2 kW machine with correct parameters gives fast, bright, burr-free results

Using 12 kW on thin sheet → too much heat, causing burn marks, yellowing, or distortion

The key is matching power and speed to thickness:

Recommended Matching

Thin sheet (0.5–2 mm): 1–3 kW, high speed, clean bright edges

Medium thickness (3–8 mm): 4–6 kW, balanced speed/power, good verticality

Thick plate (8+ mm): 6 kW or higher, but requires optimized piercing and gas control

Think of it like cooking — too much heat burns the food, too little leaves it raw.

Perfect results come from proper control, not brute force.

2. Nitrogen Doesn’t Just “Blow Out Slag” — It’s the Cosmetic Artist for Stainless Steel

Many think assist gas only blows molten metal away.

In stainless steel cutting, assist gas can influence quality even more than the laser itself.

Stainless steel resists corrosion because of its chromium oxide protective film.

If exposed to oxygen during cutting, this film is destroyed — leaving the cut edge dark or oxidized.

That’s why stainless steel must be cut with inert gas, usually high-purity nitrogen.

But nitrogen pressure matters:

Too low → molten metal isn’t expelled → bottom dross

Too high → turbulent airflow widens the kerf and causes ripples

Typical nitrogen pressure ranges

1–3 mm: 12–15 bar

6 mm and above: 18–20 bar + larger nozzle

And purity is critical:

Below 99.99%, moisture and oxygen will cause gray edges or micro-rust spots.

Saving a little money on gas can ruin an entire batch of high-value stainless parts.

3. Focal Position: The Invisible “Blade Tip” That Determines Cut Quality

A laser beam is strongest at its focal point.

You can’t see it, but its position directly determines the quality of the cut.

Focus too high (above surface) → weak energy density → poor penetration

Focus too low (deep under the sheet) → overheated upper edge, trailing burr on bottom

Best focus → at mid-thickness or slightly below → symmetric edges, good verticality

Modern systems use auto-focus heads to maintain ideal focal distance in real time.

If your machine doesn’t have it, perform a focus test:

Cut the same pattern at different Z-values on scrap material

pick the cleanest edge

save those parameters as your template.

4. Piercing Technique: Don’t Let the First Step Ruin the Entire Cut

Many users focus only on the cutting process but ignore the piercing step.

Traditional “blast piercing” (full power instantly) creates:

large entry holes

molten splashes

micro-cracks

poor starting geometry

And the cut quality deteriorates from that first point.

A better way: gradual piercing

Use low power to preheat

slowly increase power until the material penetrates.

This takes 1–2 seconds longer but produces a smooth, stable starting point.

High-end systems now automatically choose the proper piercing method based on thickness.

5. Beyond the Machine — Human Experience Still Matters Most

Even the best fiber laser is still just a tool.

Cut quality ultimately depends on the operator’s understanding and attention to detail.

For example:

Is the sheet flat? Warping affects focus height

Are the lenses clean? A dust particle scatters the beam

Is the nozzle centered? Even a 0.1 mm offset tilts the kerf

Is the toolpath optimized? Excessive stops/starts leave marks

These subtle factors aren’t in the manual.

They’re learned through testing, documenting, and improving — the real craft behind perfect cutting.

Conclusion: Great Cutting Comes From Careful Control

Fiber laser technology has made stainless steel cutting faster and more accessible.

But it hasn’t eliminated the need for craftsmanship.

In today’s era of similar equipment and fierce competition, the shops that master every detail — gas, focus, power, nozzle, path — are the ones that deliver truly premium results.

So next time you see a stainless steel part with a mirror-like edge, remember:

It’s not just the laser.

It’s also the operator behind it, and their dedication to “just right.”

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()