-

Product

-

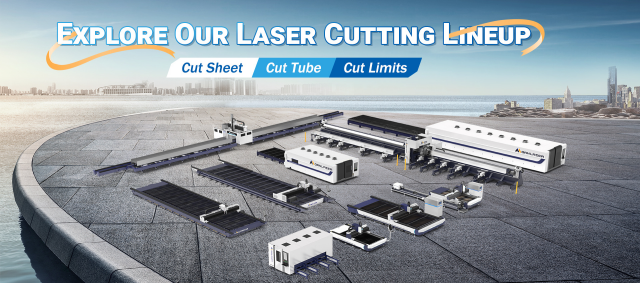

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Your Essential Laser Cutting Machine Buying Guide: Power, Bed Size, and Key Factors You Can't Ignore

2025-11-20Investing in a laser cutting machine is a major decision, whether you're expanding production, upgrading old equipment, or stepping into the metal cutting industry. With so many models, configurations, and brands on the market, choosing the right system can mean the difference between smooth production and years of costly downtime.

This guide breaks down the core dimensions you must evaluate before buying, helping you avoid hidden pitfalls and select a machine that truly fits your long-term manufacturing goals.

1. Cutting Power: Match Power to Your Materials and Output

Choosing the right power level is the foundation of your decision. A mismatch between power and production needs often results in slow cutting, poor edge quality, and unnecessary electricity consumption.

How to choose the right power:

Below 6 kW: Suitable for thin sheet metal cutting.

6 kW–12 kW: Ideal for most metal fabrication businesses with mixed materials like carbon steel, stainless steel, and aluminum.

12 kW–80 kW+: Best for high-volume industrial applications and thick metal cutting.

Modern fiber laser cutting machines deliver higher efficiency and lower operating costs compared to traditional methods, making them the preferred choice among manufacturers worldwide.

2. Bed Size & Working Area: Your Production Determines the Format

The bed size of a laser cutting machine directly affects production efficiency and material utilization. Choosing a size too small limits your capabilities; too large, and you pay for unused capacity.

Common format options:

3015 (1500×3000 mm) → Most common, versatile for metal fabrication

4020 / 6020 / 8025 → For large sheet metal processing

25120 / 31140 Custom formats → For oversized components in construction, ships, or heavy machinery

An experienced laser cutting machine manufacturer can recommend the right format based on your material size, workflow, and factory layout.

3. Machine Core Components: Where Quality Truly Matters

Even machines with the same power and format can differ dramatically in performance. The secret lies in the quality of the laser source, cutting head, water chiller, and motion system.

Key components to check:

Fiber laser source: Max, Raycus, BWT, IPG...

Laser cutting head: Boci, Raytools, Precitec...

Control system: CypCut, HypCut, Raytools...

Guide rails & motors: Determine accuracy and smoothness

A trusted laser machine manufacturer will always provide transparent component lists and certifications. If a supplier avoids these details, consider it a major red flag.

4. Brand Reputation & After-Sales Service: The Most Overlooked but Critical Dimension

In laser cutting, after-sales support determines long-term production stability.

What to look for:

Timely after-sales service

Availability of spare parts

Response time for troubleshooting

Training for operators

Long-term software upgrades

A strong laser cutting brand not only delivers reliable equipment but also ensures you maximize productivity and minimize downtime.

5. Total Cost of Ownership: Not Just the Purchase Price

The biggest mistake many buyers make is comparing only the initial price.

Consider long-term costs:

Electricity consumption

Gas consumption (oxygen/nitrogen)

Consumables (nozzles, lenses, filters)

Maintenance and service

Production downtime caused by machine instability

In many cases, a cheaper low-end machine becomes far more expensive over time due to frequent failures and poor cutting performance.

Investing in a higher-quality fiber laser cutter from a reputable manufacturer typically results in better ROI, lower maintenance, and higher cutting efficiency.

Purchasing a laser cutting machine is not just buying equipment — it's investing in the future of your business. By evaluating power, working area, brand strength, component quality, and long-term costs, you can avoid common pitfalls and ensure stable, efficient production for years to come.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()