-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

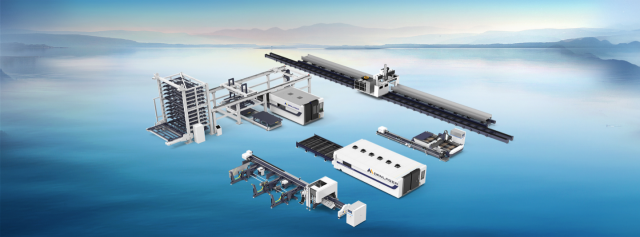

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Must-Read Guide to Buying a Laser Cutting Machine: 5 Core Factors from Power to Brand

2025-09-25Choosing the right laser cutting machine is not just about comparing prices—it's about finding the perfect match for your materials, production scale, and long-term goals. From cutting power and bed size to brand reputation and after-sales support, every detail matters. In this guide, we'll walk you through the five core factors you must evaluate before buying, helping you avoid costly mistakes and make a smart, future-proof investment.

1. Cutting Power: Match Machine Power to Your Materials

The first thing to consider is laser power. Whether you need a 1000W laser cutting machine for thin stainless steel or a 30000W fiber laser cutter for heavy carbon steel, your choice should reflect actual production needs. Leading laser cutting machine manufacturers will recommend the right power range based on your industry.

2. Working Area and Bed Size: Choose the Right Format

Laser cutting machines come in standard formats like 3000×1500mm or larger beds for oversized plates. If your shop processes non-standard sheet sizes, ask your laser cutting machine brand about customizable options. Some manufacturers even offer coil-fed laser cutting machines for continuous production.3. Precision and Stability: Look Beyond the Specs

Cutting power is nothing without accuracy. Evaluate servo systems, auto-focus capabilities, and cooling designs. Reliable laser cutting machine manufacturers ensure stability with proven components and service support.

4. Automation and Efficiency: Invest in Productivity

Today's market demands more than just cutting—it demands automation. Look for:

- Automatic loading/unloading

- Smart nesting software

- Real-time monitoring features

Top laser cutting brands often recommend tailored automation solutions to scale your production.

5. Brand and After-Sales Service: Don't Overlook Support

Choosing the right laser cutting machine brand is as important as choosing the right model. A reputable manufacturer guarantees:

- Professional training and quick support

- Long-term spare parts availability

- Proven references and customer cases

Recommendation: Always compare brand reputation and service reliability, not just specifications.

By evaluating power, working area, precision, automation, and brand, you'll avoid common pitfalls and secure long-term returns on your investment. Contact our laser cutting experts today for a personalized consultation!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()