-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

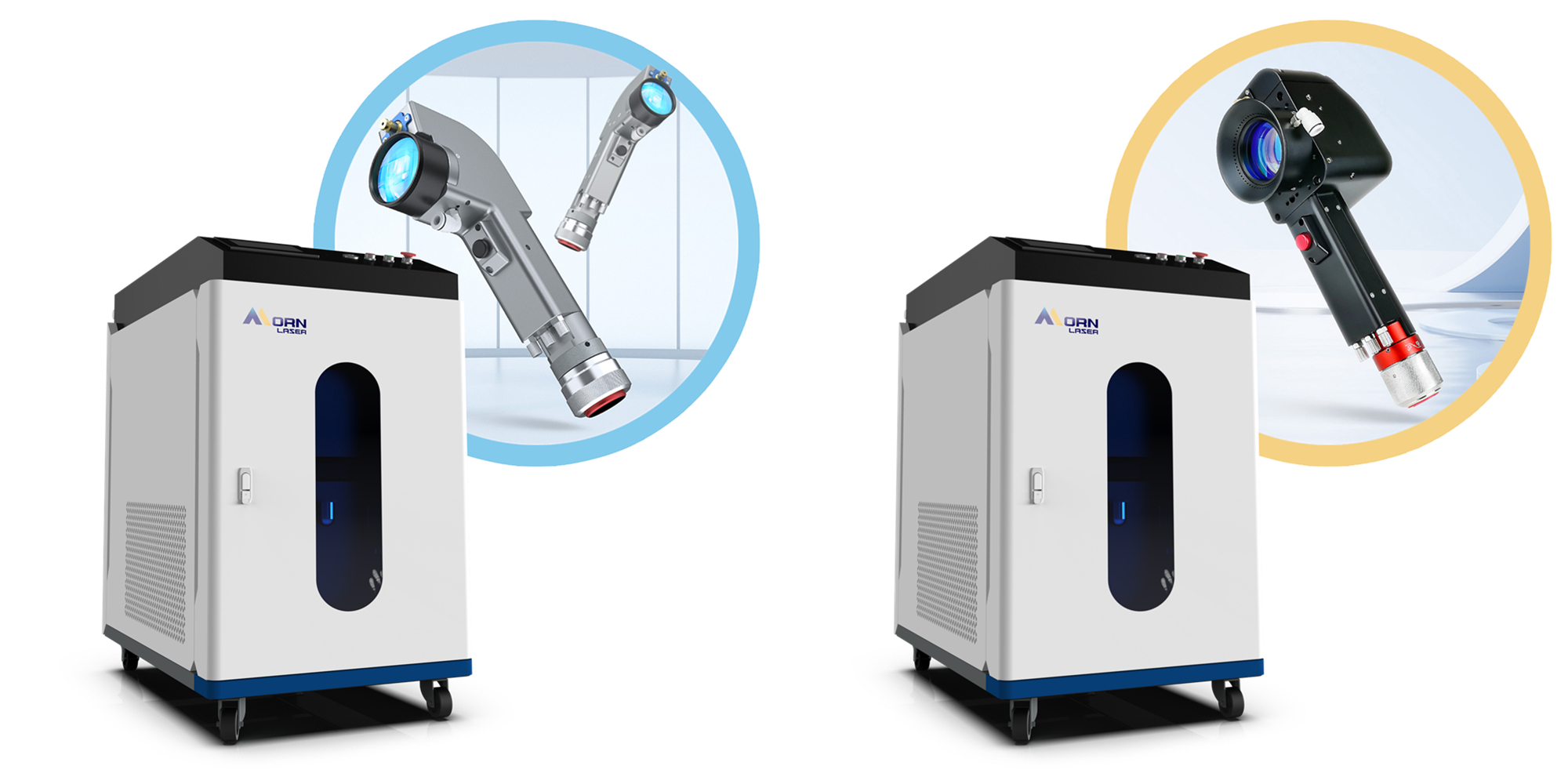

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

The Rise of Fiber Laser Cleaning Machine in Industrial Applications

2025-09-10In modern manufacturing, surface preparation and rust removal are not just routine tasks—they are critical for product quality, safety, and efficiency. Whether it’s cleaning metal components, removing rust from pipelines, or stripping paint from automotive parts, industries have long relied on methods like sandblasting, chemical cleaning, or grinding.

But these traditional approaches come with major disadvantages:

- They generate toxic waste and harm the environment.

- They require costly consumables and labor.

- They often damage the base material, reducing product lifespan.

This is where fiber laser cleaning machines step in. By using high-energy laser beams to precisely remove surface contaminants, manufacturers gain efficiency and sustainability while reducing long-term costs.

Why Industries are Adopting Laser Cleaning

1. Eco-Friendly Solution

Laser cleaning eliminates the need for chemicals and abrasive materials, reducing hazardous waste and environmental impact.

2. Cost Savings

Laser cleaning systems may require a higher upfront investment, but they significantly lower operational costs over time by:

Reducing consumable usage

Lowering labor demand

Minimizing downtime between cleaning cycles

3. Non-Destructive Process

The laser beam selectively remove contaminants like rust, paint, or oil, leaving the base material intact.

4. Automation Integration

Laser cleaning equipment can be combined with robotic arms, production lines, and CNC platforms, making them suitable for high-volume industrial applications.

Key Industrial Applications of Laser Cleaning Machine

The industrial laser cleaning machine is widely used in modern manufacturing for its non-contact surface cleaning capabilities. In the metal fabrication industry, it ensures perfectly clean surfaces before welding, coating, or adhesive bonding, which directly improves product durability and overall quality. Key applications include rust removal, paint and coating stripping, oxide layer removal, and surface preparation for welding and coating to guarantee strong weld joints and long-lasting adhesion. Laser cleaning is also widely used for the precision cleaning of molds and tools, helping manufacturers maintain high efficiency and product quality.

Laser Cleaning vs Traditional Methods

Feature

Laser Cleaning

Sandblasting / Chemicals

Environmental Impact

No chemicals, minimal waste

Hazardous waste, dust, chemicals

Surface Damage

Non-contact, no material loss

Abrasion and surface erosion

Operating Cost

Low consumables, long-term savings

High consumables and disposal costs

Automation

Easily automated

Limited automation potential

Verdict: Laser cleaning offers a safer, cleaner, and more cost-effective solution compared to traditional methods.

Laser cleaning is no longer an experimental technology—it is becoming the industry standard for surface preparation, rust removal, and coating stripping. With its eco-friendly benefits, cost efficiency, and automation potential, it offers a clear advantage over traditional abrasive methods.

Want to bring eco-friendly cleaning technology to your production? Contact Morn Laser today and discover how our advanced fiber laser cleaners can transform your operations.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()