-

Product

-

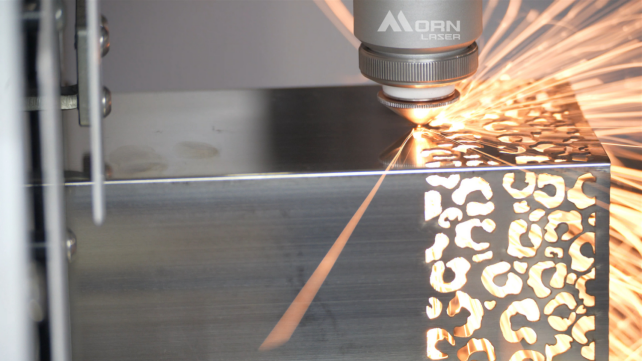

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Tube Laser Cutting vs Traditional Methods: What's Better for Your Business?

2025-08-07Whether you're in metal fabrication, furniture manufacturing, or structural engineering, precision tube cutting plays a critical role in your production quality and efficiency. But when it comes to choosing between traditional cutting methods and modern tube laser cutting machines, the decision can significantly impact your bottom line. So what's the smarter choice for your business? Let's break it down.

1. Precision and Complexity: Who Wins?

Traditional Methods:

Processes like sawing, drilling, and punching are sufficient for simple cuts but struggle with complex geometries, angles, or custom notching. Manual error and inconsistent finishes are common.

Tube Laser Cutting:

A tube laser cutting machine delivers tight tolerances and clean edges, even with complex patterns and 3D contours. Intricate cuts, bevels, slots, and holes can be completed in a single setup — no repositioning required.

Verdict:

Laser cutting is unmatched in precision, especially for intricate or decorative tube designs.

2. Speed and Efficiency

Traditional Methods:

Multiple steps are needed — measuring, marking, sawing, deburring, drilling — and each adds time and cost. Tool changeovers and material handling further slow production.

Tube Laser Cutting:

A tube laser cutter can cut, bevel, and slot in one go. Combined with automatic loading/unloading, production speed increases dramatically. Batch production becomes more scalable.

Verdict:

Laser cutting slashes processing time and increases throughput for high-volume operations.

3. Labor and Skill Dependency

Traditional Methods:

Skilled workers are needed to ensure accuracy and quality, especially when operating different machines or interpreting drawings manually.

Tube Laser Cutting:

Automated systems reduce labor dependency and training requirements. Once programmed, even operators with minimal experience can run jobs with consistent results.

Verdict:

Laser machines reduce reliance on highly skilled labor and lower training costs.

4. Material Waste and Tool Wear

Traditional Methods:

Mechanical cutting tools wear over time, leading to inaccuracies and the need for frequent maintenance. Material waste is often higher due to manual error and large cutting gaps.

Tube Laser Cutting:

As a non-contact process, laser cutting minimizes tool wear. Nesting software helps optimize material usage, and precision cuts reduce scrap rates.

Verdict:

Laser cutting systems are more cost-efficient in the long run due to less waste and lower maintenance.

5. Customization and Flexibility

Traditional Methods:

Changeovers between product types or materials can be time-consuming. Designing custom joints or tab-slot structures requires additional tools or processes.

Tube Laser Cutting:

With just a digital file, you can switch between projects instantly. Creating custom joint geometries like fishmouth cuts or interlocking slots is fast and repeatable.

Verdict:

Laser cutting offers unmatched flexibility for prototyping, short runs, and high-mix production environments.

6. Initial Investment vs Long-Term ROI

Traditional Methods:

Lower upfront cost, but hidden costs add up — tooling, maintenance, skilled labor, slower production, and more waste.

Tube Laser Cutting:

Higher initial investment, but faster ROI thanks to higher productivity, lower labor costs, and better quality control.

Verdict:

Laser systems pay for themselves faster in high-demand, precision-focused operations.

Final Thoughts: Which Is Right for You?

If your business demands precision, speed, and the ability to adapt quickly to design changes or market shifts, laser tube cutting machine is the clear winner. It transforms your tube fabrication workflow — reducing lead times, improving accuracy, and ultimately giving you a competitive edge.

But if you're only cutting simple shapes in small volumes, traditional methods may still serve your needs for now.

Ready to upgrade your production line? Explore Morn Laser's high-performance tube laser cutting machines and see how automation can reshape your fabrication process!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()