-

Product

-

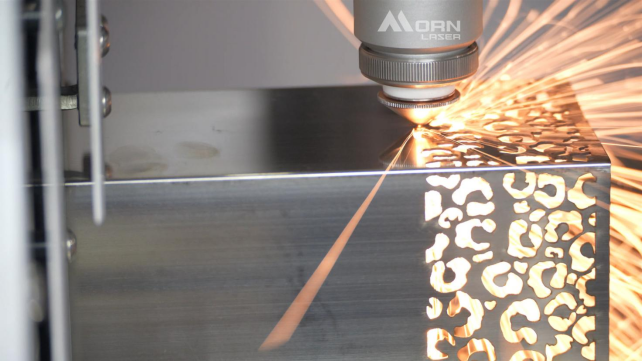

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Tube Laser Cutting Machine: A Key to Enhancing Manufacturing Competitiveness

2025-02-25In modern manufacturing, as production tasks become more complex and market demands diversify, the companies need more efficient and flexible production equipment to stay competitive. The tube laser cutting machine, a new type of metal tube cutting tool, is helping companies improve production efficiency, respond to market changes, and meet diverse production needs with its powerful processing capability and flexibility.

Meeting Diverse Production Demands: Customization and Flexible Production

As demand for personalized customization and small batch production continues to grow, traditional production methods are gradually revealing their limitations. Traditional tube cutting equipment often requires frequent mold or tool adjustments and cannot quickly adapt to the production demands of different products, resulting in longer production cycles and increased costs. In contrast, the laser tube cutting machine, with its high precision and rapid response, can meet the growing demands for diversified production.

The tube laser cutter does not rely on molds, and only cutting data needs to be input during production. It can quickly cut metal tubes of various diameters, thicknesses, and materials, whether it's for standard batch production or customized, small batch production. This flexibility makes the tube laser cutting machine an indispensable tool in manufacturing, helping companies remain agile in a fast-changing market.

Improving Production Efficiency: Accelerating Product Delivery Times

With the intensification of market competition, companies face increasingly stringent delivery time requirements. Traditional tube cutting methods often take a long time for cutting and post-processing, while the high-speed cutting capability of the tube laser cutter can significantly shorten production cycles and speed up product delivery. The pipe laser cutting machine not only cuts various types of tubes quickly but also features an automated control system that reduces human intervention, further enhancing production efficiency.

For high-volume production scenarios, the advantages of the laser tube cutting machine are even more evident. Companies can configure highly efficient laser tube cutting machines to complete large-scale tube cutting tasks quickly, significantly increasing overall production capacity.

Environmentally Friendly and Sustainable Development

As environmental requirements continue to rise, manufacturing equipment is increasingly shifting towards eco-friendly and energy-efficient solutions. The laser pipe cutting machine not only offers high efficiency and precision but also minimizes material waste, optimizes resource utilization, and reduces energy consumption during production. Additionally, the heat-affected zone generated during laser cutting is smaller, reducing material damage and further enhancing the environmental friendliness of the production process.

For companies that need to meet green manufacturing standards, the tube laser cutting machine is undoubtedly an ideal choice. Its low pollution and low energy consumption help companies achieve sustainable development while ensuring efficient production.

As an essential tool in modern metal manufacturing, the laser tube cutting machine not only improves production efficiency but also enhances a company’s flexibility in responding to market changes. Its advantages in customization, cost savings, and eco-friendly manufacturing make it an innovative solution in the metal tube processing sector.

With the arrival of the Industry 4.0 era, laser tube cutting machines will continue to drive the manufacturing industry toward smarter, more efficient, and greener production, becoming key equipment for businesses to enhance competitiveness and meet future challenges.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()