-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

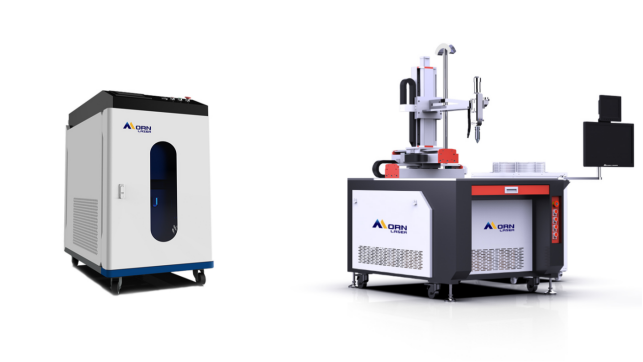

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Laser Welding vs Traditional Welding: Which Is Best for Modern Fabrication?

2025-06-19The Big Debate: Is Laser Welding Replacing Traditional Welding?

In today's fast-paced manufacturing landscape, every second counts—and every weld matters. While MIG, TIG, and arc welding have long been the industry standard, laser welding is rapidly transforming how manufacturers think about metal welding.

So, what's the real difference? And more importantly—which welding method is best for your business in 2025?

What Is Laser Welding?

Laser welding uses a concentrated laser beam to heat and fuse metals. It's a non-contact process, highly precise, and suitable for thin or delicate parts.

Two major formats:

Handheld Laser Welding Machine – ideal for flexibility and on-site work

Platform Automatic Laser Welder – for high-volume, precision welding in factories

Traditional Welding at a Glance

MIG (Metal Inert Gas) – fast and easy to learn, great for thick metals

TIG (Tungsten Inert Gas) – high precision, ideal for thin metals but slow

Stick Welding – versatile, but less clean and more spatter

Laser Welding vs Traditional Welding: Head-to-Head Comparison

Feature

Laser Welding

Traditional Welding (MIG/TIG/Stick)

Speed

2–10× faster

Moderate to slow

Heat Affected Zone

Very small (minimal distortion)

Large (prone to warping)

Skill Requirement

Easy to learn, intuitive handle

Requires experienced welders

Material Thickness

Best for thin metals

Better for thicker sections

Finish Quality

Smooth, minimal post-processing

Often needs grinding or polishing

Portability

High (handheld units)

Lower, bulky and setup-heavy

Spatter/Fumes

Very low

High, needs fume extraction

Automation Ready

Yes (robots, CNC)

Less compatible with automation

Why More Fabricators Are Switching to Laser Welding

Reduced labor costs—1 operator can do the work of 2–3 welders

Faster production cycles—ideal for just-in-time manufacturing

Cleaner workstations—less smoke, spatter, and cleanup

More sustainable—lower power consumption and waste

Easy training—new operators can be trained in hours, not weeks

Best Use Cases for Laser Welding Machine

Industry

Applications

Sheet Metal

Cabinets, panels, frames

Kitchenware

Stainless steel sinks, appliances

Battery Packs

EV battery cases, tab welding

Medical

Surgical tools, stainless tubing

Aerospace

Thin aluminum, high-precision welds

Furniture

Steel chair/desk frames, handrails

What to Look for in a Fiber Laser Welding Machine

✔ Stable fiber laser source

✔ Lightweight, ergonomic welding gun

✔ Wire feeder for filling gaps

✔ After-sales support and training

Why Choose Morn Laser for Laser Welding Solutions

Over 17 years of laser manufacturing experience

Free welding samples with your materials

Free training & lifetime technical support

Easy-to-use interface, multi-language support

Factory-direct pricing and CE/FDA/ISO-certified machines

Get Started with Laser Welding Today

Laser welding isn't the future—it's the now. Whether you're a job shop or a high-volume manufacturer, upgrading your welding process can transform your output and profits.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()