-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

Fiber Laser Cleaning Machine: The Ideal Choice for Green Manufacturing and Efficient Cleaning

2025-04-29As global manufacturing continues to raise standards for environmental protection and production efficiency, traditional cleaning methods are being rapidly replaced. In industries such as metal processing, automotive manufacturing, ship maintenance, and electronics production, the demand for high-efficiency, eco-friendly, and non-damaging surface cleaning technologies is growing steadily.

In the past, methods like sandblasting, chemical solvent cleaning, and high-pressure water cleaning were widely used, but they came with significant drawbacks: severe pollution, high labor costs, complicated processes, and the risk of damaging material surfaces.

With increasingly stringent environmental regulations worldwide and growing demands for cleaner production processes, fiber laser cleaning machines have quickly gained market favor thanks to their eco-friendly, non-contact, and highly efficient advantages.

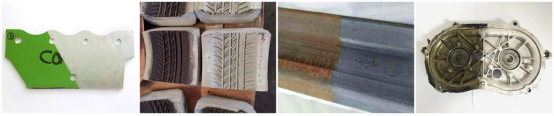

As technology matures and equipment costs become more affordable, fiber laser cleaning machines have been widely adopted across various industries:

- Metal Processing: Quickly removes rust and oxide layers from steel, aluminum, and alloy surfaces.

- Machinery Manufacturing: Effectively cleans grease and contaminants from mechanical parts.

- Shipbuilding and Marine Engineering: Removes stubborn rust and old coatings from decks and hull surfaces.

- Automotive Manufacturing: Cleans weld seams and treats mold surfaces, enhancing the efficiency of parts processing.

Laser cleaning machines not only boost production efficiency but also help companies achieve their green and sustainable development goals. Demand for industrial laser cleaning equipment continues to grow across various industries, with portable laser cleaning machine and handheld laser cleaning machine becoming particularly popular choices for equipment procurement.

Why choose a fiber laser cleaning machine now?

- Meets Environmental Standards: Safe, eco-friendly, and pollution-free, fully complying with environmental regulations.

- Saves Production Costs: No consumables required, low maintenance, and reduced labor costs.

- Improves Cleaning Efficiency: Operable by one person, offering continuous and highly efficient cleaning.

- Enhances Business Competitiveness: Green manufacturing has become a global trend, making eco-friendly production essential for staying competitive.

For manufacturing companies looking to upgrade their cleaning technology and enhance market competitiveness, choosing an advanced industrial laser cleaning machine is not just an investment in production but also a proactive strategy for staying ahead of future market trends.

Whether you need a 1000W, 1500W, 2000W, or 3000W laser cleaning machine, or an automatic laser cleaning machine integrated with robotic arm system, we can offer the professional match for your needs. Consult us now to get the industry application cases and latest laser cleaning machine price now!

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()