-

Product

-

Fiber laser cutting machine

-

Profile Steel/ H-Beam Laser Cutter

high efficiency | high-performance | high quality -

Full Cover Fiber Laser Cutting Machine

supreme configuration | high precision | safe & pollution-free -

Sheet fiber laser cutting machine

tailor-made machine | efficiency boost -

Fiber Laser Bevel Cutting Machine

one-shot bevel | efficiency boost | streamlined process -

High precision fiber laser cutting machine

High precision | small footprint | fully enclosed -

Four-chuck Tube Cutting Lasers

truly zero-tailing | low cost per part | auto loader -

Three-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Two-chuck Tube Laser Cutting Machine

top production output | low cost per part | extremely short tailing -

Full Enclosed Fiber Laser Cutting Machine

Integrated design saves installation time and shipping costs. - flexible processing | continuous cutting | efficient production

-

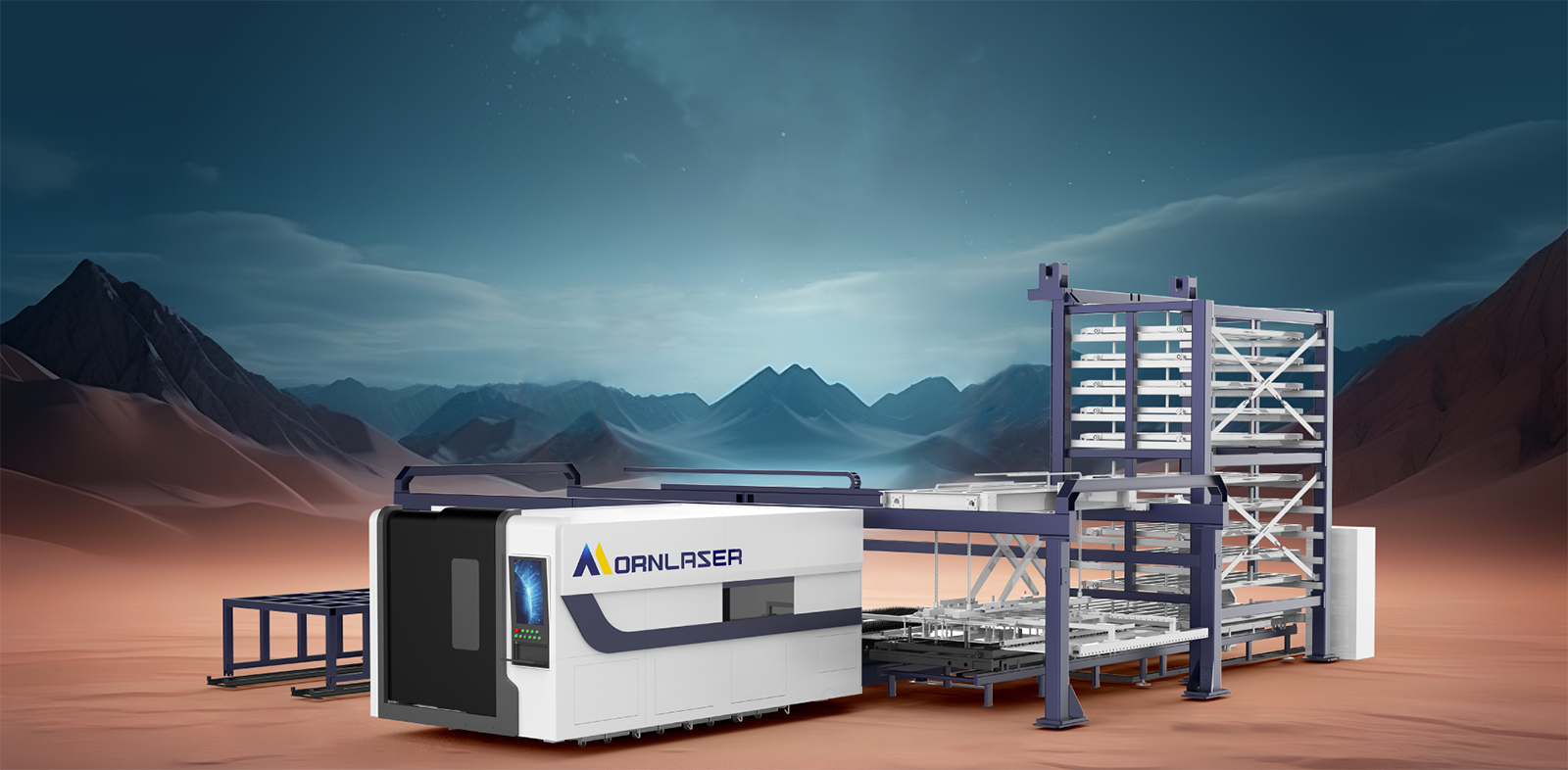

Fully Automatic Loading & Unloading Laser Cutting Production Line

intelligent production | optimizing factory space | reduce labor costs -

Sheet and Tube Fiber Laser Cutting Machine

supreme cost-effectiveness | dual-use laser | space-saving

-

-

Fiber laser welding machine

-

Air-cooled Portable Laser Welding Machine

more flexibility | easy to use | cost effective -

Automatic laser welding machine

fine welding seam | boosted efficiency -

Integrated fiber laser welding machine

instant welding | easy to operate & move -

Handheld fiber laser welding machine

long distance welding | multi-welding modes

-

- Fiber laser cleaning machine

- Bending Machine

-

Fiber laser cutting machine

- Solutions

- Why Morn Laser

- Price

- Contact

- VR

Menu

X- home

-

Product >

-

How to Choose the Right Coil-fed Laser Cutting Machine

2024-12-23Choosing the right coil-fed laser cutting machine is crucial for optimizing your production process and ensuring high-quality output. With advancements in smart manufacturing technology, selecting a machine that fits your specific requirements can lead to significant improvements in efficiency, precision, and cost-effectiveness. This guide will help you make an informed decision when choosing a coil-fed laser cutting machine.

Key Features to Consider

1. Acceleration and Speed

- Look for machines with high acceleration capabilities (e.g., 1.5G) and fast linkage speeds (up to 140m/min). These specifications ensure smooth transitions and rapid processing times, which are essential for maintaining high productivity levels.

2. Cutting Thickness

- Determine the maximum thickness of material you need to cut. For example, if you work with stainless steel, a machine capable of cutting up to 100mm thickness would be ideal. This ensures versatility and adaptability to various projects.

3. Laser Power

- The laser power (such as 60,000W) directly affects the machine's ability to handle different materials and thicknesses efficiently. Higher power means greater flexibility and faster cutting times.

4. Automation Capabilities

- Opt for models with automatic loading and unloading systems. Automation not only reduces labor costs but also minimizes errors and enhances safety in the workplace.

Additional Considerations

- Brand Reputation and Support

- Choose a reputable manufacturer like MOrnlaser, known for its 16 years of R&D experience and top-tier sales in China. A reliable brand offers better support, maintenance services, and long-term reliability.

- Energy Efficiency and Environmental Impact

- Consider machines designed for energy efficiency and those that help achieve environmental goals. Reducing energy consumption and emissions can lower operational costs and improve sustainability.

-Customization Options

- Some manufacturers provide customization options to tailor the machine to your specific needs. This can include software integration, additional tooling, or specialized accessories.

Conclusion

Selecting the right coil-fed laser cutting machine involves evaluating multiple factors, from performance specifications to automation features and beyond. By carefully considering these elements, you can find a solution that not only meets your current production needs but also supports future growth and innovation. MOrnlaser’s advanced technology and commitment to excellence make it a standout choice for businesses looking to enhance their manufacturing processes through smart automation.

- Office Address:

- 17F, Building 5, Qisheng Mansion High-Tech Zone, Jinan, Shandong 250101, China

- Email: info@mornlaser.com

- Mobile/WhatsApp/WeChat: +86 151 6916 6350

CONTACT USCopyright © 2008-2022 Morn Laser All Rights Reserved.![]() Get a Quote

Get a Quote

![]() Get a Quote

Get a Quote

Cookies

We use cookies to improve our services and remember your choice for future visits. By clicking "Accept cookies", you consent to the use of cookies on this website.

Read our Privacy Policy

Get a Quote x

![]()